Tim Sievers is awarded the MedK scholarship by the Faculty of Medicine

Our newly recruited doctoral student Tim Sievers has been invited to join the Medical College (MedK) program. The scholarship is aimed at medical students at the University of Münster who want to write experimental dissertations and, in addition to financial support, also offers support through seminars and lectures to give young scientists a good start in research practice. In addition, the college also offers the opportunity for regular exchange with other young and motivated students who want to contribute to research, as well as with experienced mentors who set the right course for the students.

Tim is working with Arturo Silvero Isidre from the Department of Neurosurgery on the implementation of expandable retractors made of polyetheretherketone (PEEK) for use in neurosurgery. These instruments are designed to facilitate surgery even in deep and hard-to-reach areas of the brain. In addition, 3D printing of such surgical instruments offers the possibility of adapting them to any anatomical peculiarities of patients or responding to the specific wishes of surgeons. This project thus contributes to individualized medicine and, thanks to the retractor's sterilizability, represents a step toward more sustainable healthcare.

We are delighted to welcome Tim to the Medical College and look forward to working with him!

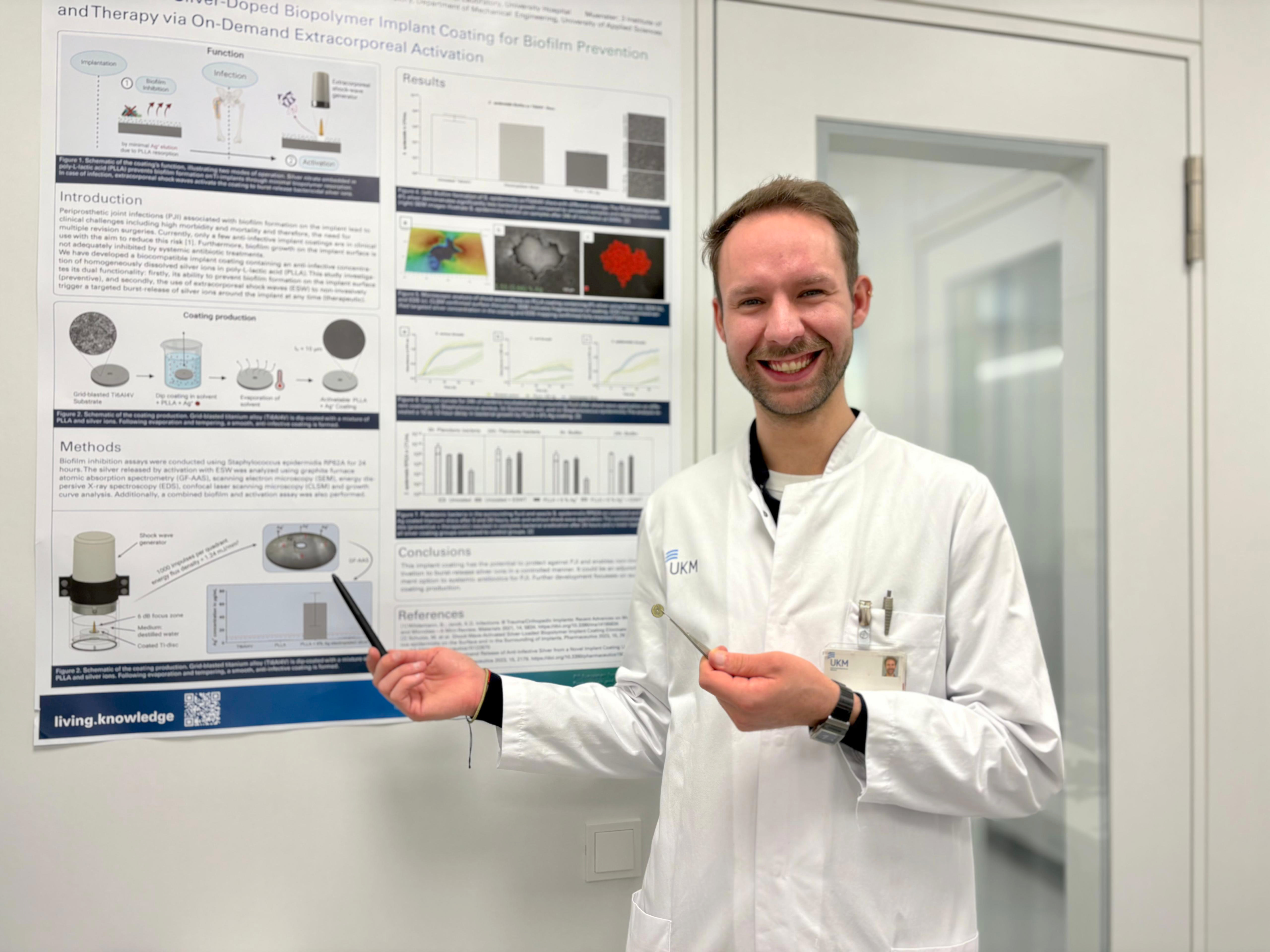

Julian Hasselmann receives add-on fellowship from the Joachim Herz Foundation

We congratulate our research assistant and doctoral student Julian Hasselmann on receiving the Add-on Fellowship from the Joachim Herz Foundation!

The foundation supports outstanding researchers in the early stages of their careers who are working in interdisciplinary and socially relevant fields. Acceptance into the fellowship provides financial and non-material support as well as access to a strong network of committed young researchers from all over Germany.

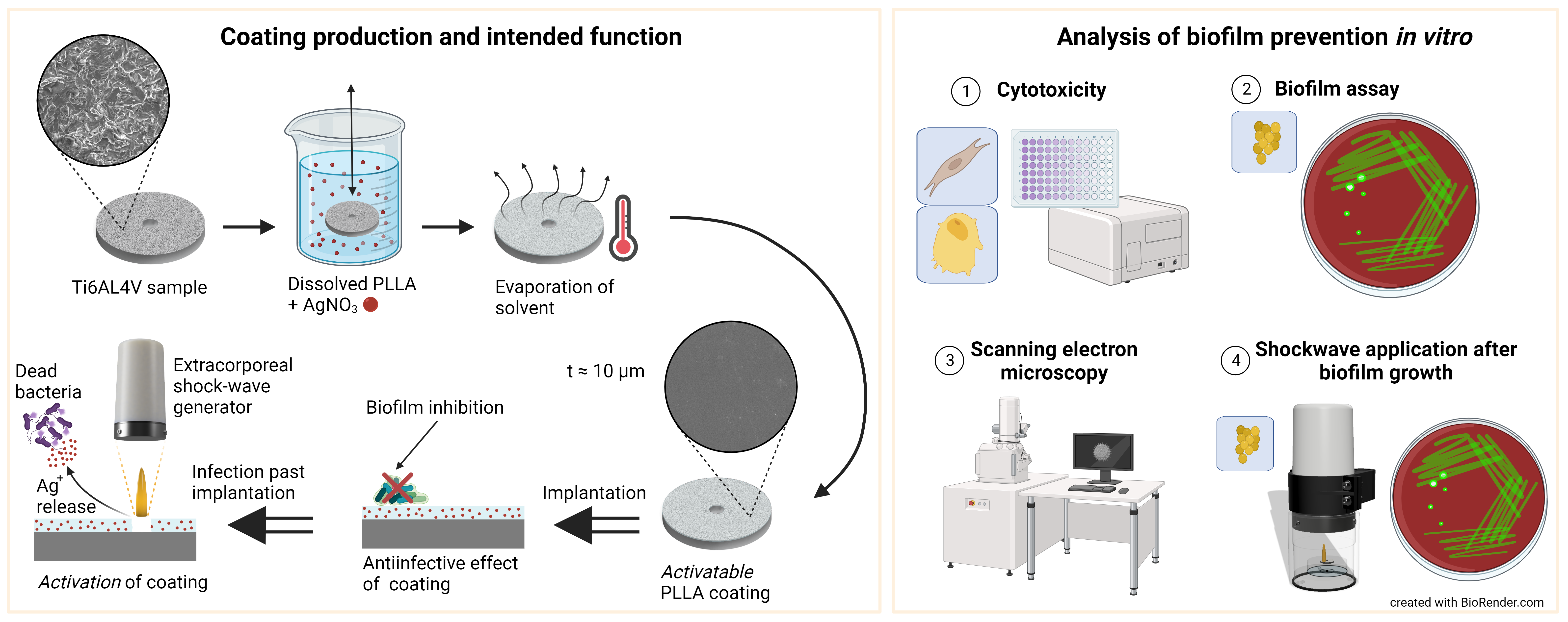

The fellowship will advance research on our activatable anti-infective implant coating. The aim of the project is to optimize the extracorporeal activation of coated implants using focused shock waves to enable the controlled release of antimicrobial agents. In particular, the project will focus on the development of a novel testing system for the precise characterization of energy transfer under clinical conditions and the investigation of various implant materials and shock wave systems.

The project thus not only contributes to the development of a clinically relevant activation protocol, but also makes an important contribution to a more resource-efficient and sustainable approach to healthcare. The research addresses key issues for the future, such as health, technological innovation, and responsible use of resources.

We are delighted to receive this award and look forward to further collaboration and scientific development!

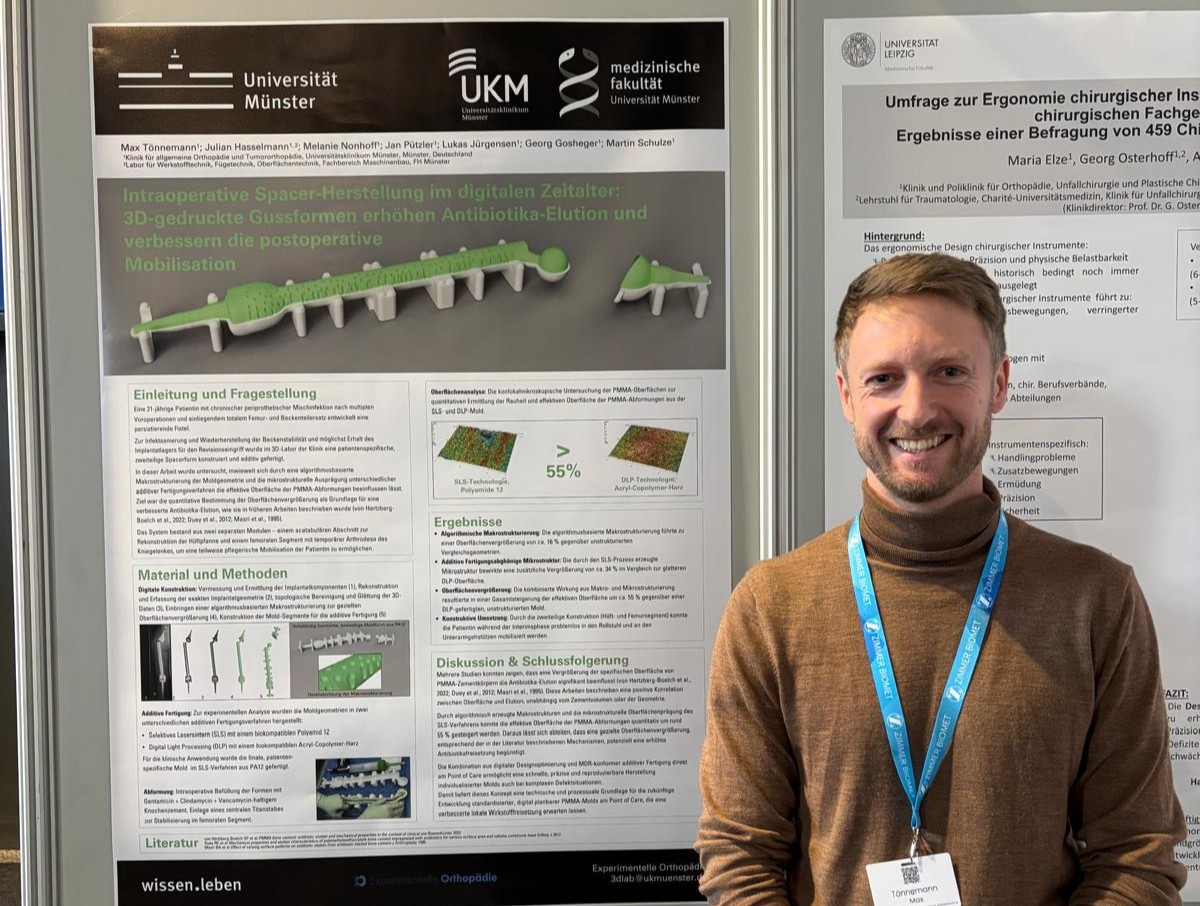

Visit to DKOU 2025 in Berlin – Designing progress together.

From October 28 to 31, 2025, our Experimental Orthopedics team once again took part in the German Congress for Orthopedics and Trauma Surgery (DKOU) in Berlin.

This year, we were again able to present several contributions on our current research focuses—from innovative antibacterial implant coatings to individualized 3D-printed spacer solutions for revision endoprosthetics. Our doctoral student Melanie Nonhoff presented a basic research study on the effectiveness of a silver coating in combination with shock wave therapy for eliminating bacterial biofilms, while Max Tönnemann presented the development of 3D-printed spacer molds that enable improved antibiotic release and postoperative mobilization.

PD Dr. Dr. Martin Schulze presented the current progress of our activatable antibacterial coating for revision hip arthroplasty in the session “AG Implant Safety | Improving Compatibility and Avoiding Damage” (Chairs: PD Dr. Daniel Klüß, Prof. Dr. Veit Krenn, and Prof. Dr. Matthias Woiczinski). The technology combines a silver-PLLA coating with the possibility of targeted activation by shock waves. It thus continues to pursue the goal of controlling infections on implants in a non-invasive manner and improving compatibility in the long term.

All presentations were received with great interest and led to intensive discussions about the clinical application of our translational research approaches.

The DKOU remains a central platform for us for scientific exchange and the presentation of innovative solutions at the interface between medicine and technology. We would like to thank the organizers for an exciting congress and look forward to continuing to advance our developments in the coming year.

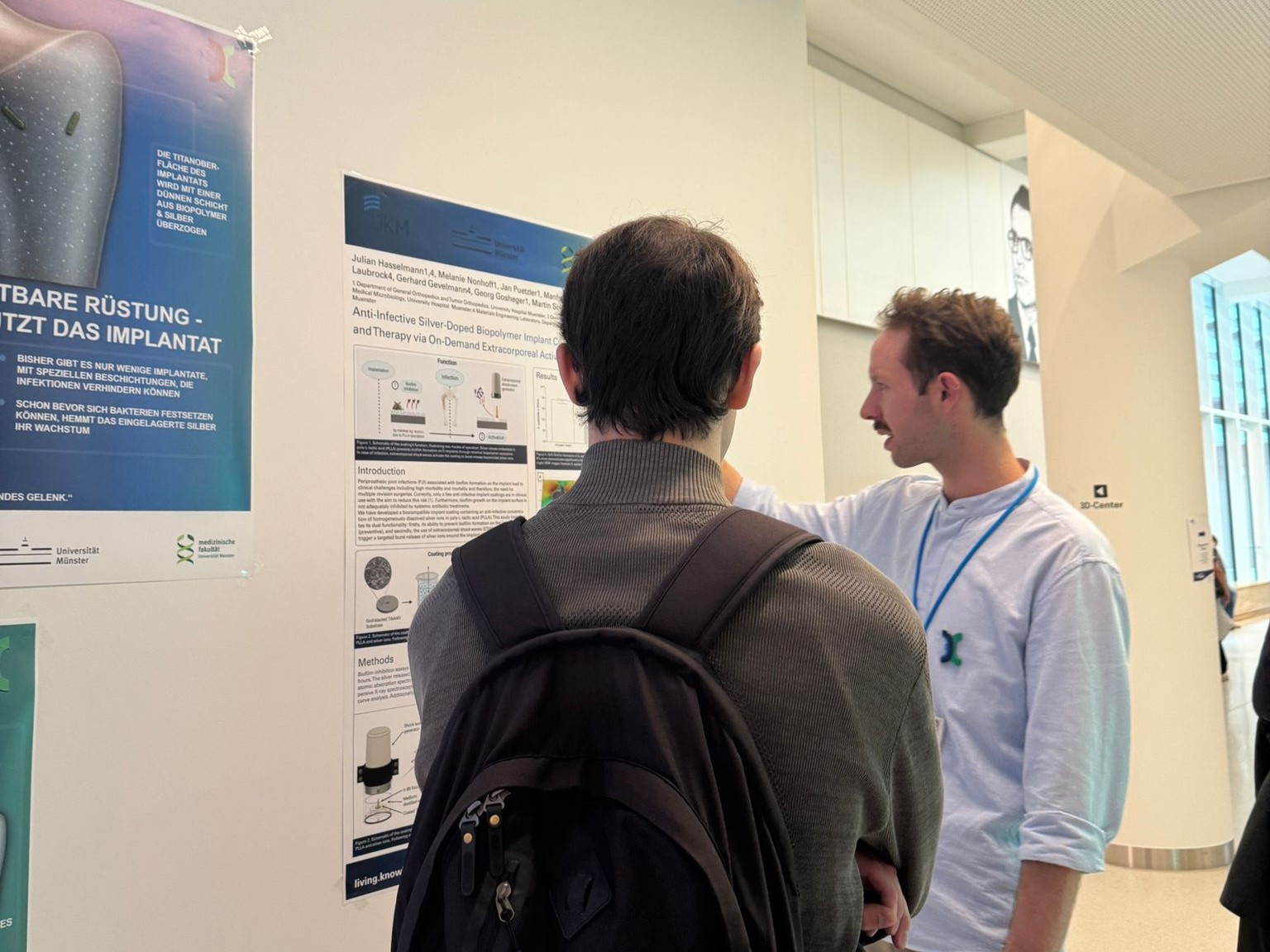

Great visitor interest at the Long Night of University Medicine – experience 3D printing up close

On September 12, the “Long Night of University Medicine” once again invited thousands of guests to discover the diversity of research, teaching, and patient care at the UKM up close. The event also marked the highlight of the 100th anniversary of University Medicine Münster and offered a colorful program for young and old alike – from hands-on activities to spectacular insights into everyday clinical life.

Experimental Orthopedics was also represented with its own contribution. Under the motto “From digital model to real implant – 3D printing at the UKM,” we took visitors on regular tours of the 3D Lab. There, they could experience how digital designs are turned into patient-specific models, aids, and implants that are used directly in the operating room. The program was complemented by exciting insights into our research work on anti-infective implant coatings.

Another special highlight was our new team member “Frankie”: a skeleton assembled entirely from 3D-printed anatomical models, which now serves to illustrate the diversity of our work. It delighted many guests.

We would like to thank all visitors for their great interest and the many stimulating discussions, as well as the UKM organization team for the successful event.

Successful defense of dissertation: Lukas Jürgensen researches individualized tumor care with 3D printing and navigation

We would like to congratulate Lukas Jürgensen on successfully defending his doctoral thesis at the Faculty of Medicine at the University of Münster. His thesis, entitled “The development and evaluation of a process-oriented concept for the individualized care of tumor patients in orthopedics using 3D printing and navigation,” was supervised by Dr. Martin Schulze and Prof. Walter Heindel.

The dissertation focused on the question of how modern 3D printing and navigation techniques can be used to make the care of orthopedic tumor patients more individualized and safer. Lukas Jürgensen developed a process-oriented concept that focuses on patient safety and quality assurance. Using real CT data, he was able to show that patient-specific solutions can be implemented more precisely and potential sources of error can be systematically reduced.

We are delighted that Lukas Jürgensen will remain with our team as a resident physician and will continue to actively shape research into the use of additive manufacturing in orthopedics in the future.

We are proud of this outstanding achievement and wish Lukas all the best for his future scientific and professional career!

Congratulations on their Bachelor's degree: Michel Bauer and Isabelle Schubert revolutionize prosthesis production with "RapidProsthetics"

We would like to congratulate Michel Bauer and Isabelle Schubert on successfully completing their Bachelor's degree at the Münster School of Design at Münster University of Applied Sciences. Their joint thesis entitled "RapidProsthetics - Development of digital product design strategies to optimize additive manufacturing processes in orthopaedic care" was developed in close cooperation with the 3D-Lab and was awarded the best thesis of their year.

The focus was on the development of a fully digitally supported process for manufacturing modular arm prostheses directly in a clinical environment. With the help of 3D scanning technology, CAD modelling and additive manufacturing (SLS and FFF printing processes), the two graduates succeeded in digitizing traditionally manual and time-consuming work steps. Their innovative solution considerably simplifies existing manual processes, saves valuable resources and drastically reduces waiting times for patients.

Their award-winning work makes an important contribution to the future of orthopaedic care and combines design excellence with engineering precision and medical relevance. We are proud of this outstanding achievement and wish Michel and Isabelle all the best for the future!

Our experts publish guide to 3D printing in medicine

We are pleased to announce an important contribution to the further development of medical 3D printing. PD Dr. Dr. Martin Schulze, Head of our 3D-Lab, and our colleague Max Tönnemann from the Experimental Orthopaedics team co-authored a new white paper that provides practical guidance for the EU MDR-compliant manufacturing of medical devices directly at the point of care. The document published by TÜV SÜD is entitled "EU MDR - Successfully navigating point-of-care and health institution exemptions" and is aimed at hospitals wishing to use additive manufacturing processes for patient-specific medical devices.

The guide addresses a key challenge in modern clinical operations: how can healthcare facilities take advantage of 3D printing for customized implants and treatment aids without violating regulatory requirements? The white paper presents a four-step workflow that covers all necessary steps from quality management system setup to risk management and verification. With their expertise in the field of additive manufacturing and personalized medical technology, our colleagues have contributed valuable insights into the practical implementation of these innovative technologies and the white paper was created in collaboration with the MGA Industrial AM Network (Mobility/Medical goes Additive e.V.), a network for promoting the clinical application of additive manufacturing processes.

Click here for the Paper

3D-Lab presents 3D printing innovations at the SchlauRaum Festival

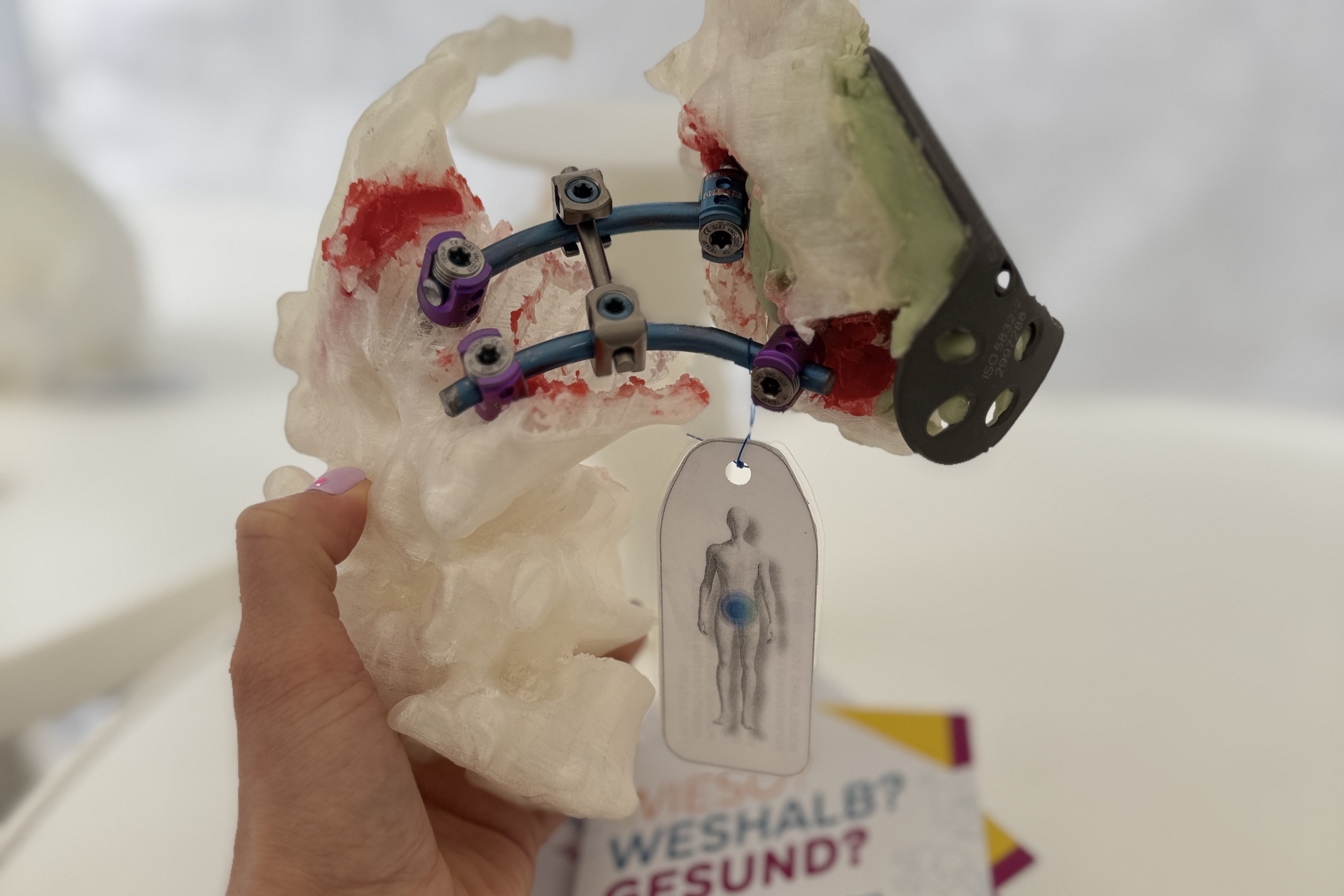

The team from the 3D-Lab at Münster University Hospital successfully participated in this year's SchlauRaum science festival, which took place from July 5 to 11 under the motto “Wieso? Weshalb? Gesund?” ("Why? Why? Healthy?") turned the whole of Münster into a campus. On Monday afternoon, PD Dr. Dr. Martin Schulze and Max Tönnemann from our team provided information on “Additive manufacturing at the point of care - 3D printing as a future technology for individualized medicine” at the knowledge stand in Stubengasse. Visitors were given a practical insight into the current state of additive manufacturing and learned how 3D printing is already helping to improve patient care.

The highlight was the evening lecture "Limitless health? How prevention and therapy benefit from digital transformation and 3D printing", which was given by PD Dr. Dr. Martin Schulze and Julian Hasselmann from our team together with Prof. Dr. Miriam Laubrock from Münster University of Applied Sciences. The interdisciplinary presentation illustrated how the close collaboration between engineering and medicine opens up new avenues for personalized, efficient and future-oriented healthcare. The SchlauRaum Festival, a joint event organized by Münster Marketing, the University of Münster, Münster University of Applied Sciences and the UKM, thus provided an ideal platform to present the innovative research work of the 3D-Lab to a broad public.

Future medicine in 3D printing: UKM expertise represented at EHFAM

At this year's European Healthcare Forum for Additive Manufacturing (EHFAM) in Basel, everything revolved around the future of patient-centered care through 3D printing at the point of care. In the panel discussion “Personalized Care On Demand”, PD Dr. Dr. Martin Schulze and international experts shed light on how site-specific solutions can enrich everyday clinical practice, always in compliance with high quality standards and a clear regulatory framework.

In the pitch competition, Max Tönnemann from our team presented how patient-specific 3D models improve the treatment of newborns with complex cardiac malformations. These innovative technologies support the UKM team in precisely planning even highly complex interventions. We would like to thank the organizers for a top-class forum and look forward to seeing you again at the next EHFAM!

Congratulations on your Bachelor's degree: Arne Pollmanns successful with innovative work on implant coating

Congratulations to Arne Pollmanns on successfully completing his Bachelor's degree! Entitled “Design, Setup, and Validation of a Fully Automated Process Flow for the Application of Biopolymer-Based Anti-Infective Implant Coatings,” his thesis was written in cooperation with the Department of Physical Engineering at Münster University of Applied Sciences. The thesis focused on developing a fully automated coating system for implants that combines biological materials and silver to prevent infections caused by bacterial colonization.

Arne developed a prototype for automated tempering, drying, dip coating, and sample guidance, as well as the concept of a programmable portal robot. His work contributes significantly to the future application of antibacterial implant coatings, combining engineering precision with medical relevance. We are proud of this achievement and wish Arne all the best in the future!

EKFS Alumni Day 2025: Exchange, awards and prospects for the future of medicine

The second Alumni Day hosted by the Else Kröner-Fresenius Foundation (EKFS) took place on 16 May 2025 at Haus am Dom in Frankfurt am Main. With the theme of 'Therapies of the Future', the event featured a diverse programme comprising specialist presentations, a high-calibre panel discussion, and the formal presentation of publication awards. EKFS-funded project leaders were invited, including PD Dr. Martin Schulze and Julian Hasselmann, who are currently conducting an EKFS-funded project on our implant coating.

Dr Susanne Meinert, a colleague from the Institute of Translational Psychiatry, was also in attendance and received one of the highly sought-after prizes for one of her publications. Alumni Day offered not only exciting content-related insights, but also many opportunities for collegial exchange and networking within the EKFS community.

Julian Hasselmann presents research on implant coating at BioMAT 2025

From May 14 to 15, 2025, he participated in the 8th BioMAT Congress in Weimar, presenting his latest research findings on our implant coating. The congress, which takes place every two years, brings together experts from science, industry, and medicine to discuss advances and challenges in the field of biomaterials. Presentations, posters, and technical discussions demonstrated the central role of innovative materials in future medicine, especially in biological environments.

In his poster presentation, Hasselmann demonstrated that our implant coating effectively protects against bacterial colonization and can treat existing infections through extracorporeal shock wave activation. The preclinical results demonstrate a significant reduction in biofilm formation and complete bacterial eradication within 24 hours of activation. Participating in BioMAT 2025 provided an excellent opportunity to exchange ideas with the expert panel and discuss future applications of our technology.

Network Without Borders: 3D Dialogue in Nijmegen

On May 12, 2025, PD Dr. Martin Schulze, head of the 3D-Lab at Münster University Hospital, visited the Radboudumc in Nijmegen with a small delegation from UKM. There, he met Prof. Thomas Maal, head of the 3D lab, in person for the first time. The meeting focused on exchanging ideas about innovative 3D technologies and their application in clinics.

In addition to gaining exciting insights into the Dutch healthcare system, the ultra-modern Innovation Park located at the point of care was particularly impressive. The visit provided an ideal opportunity to strengthen existing connections and promote cross-border collaboration. A return visit to the UKM is planned for fall 2025.

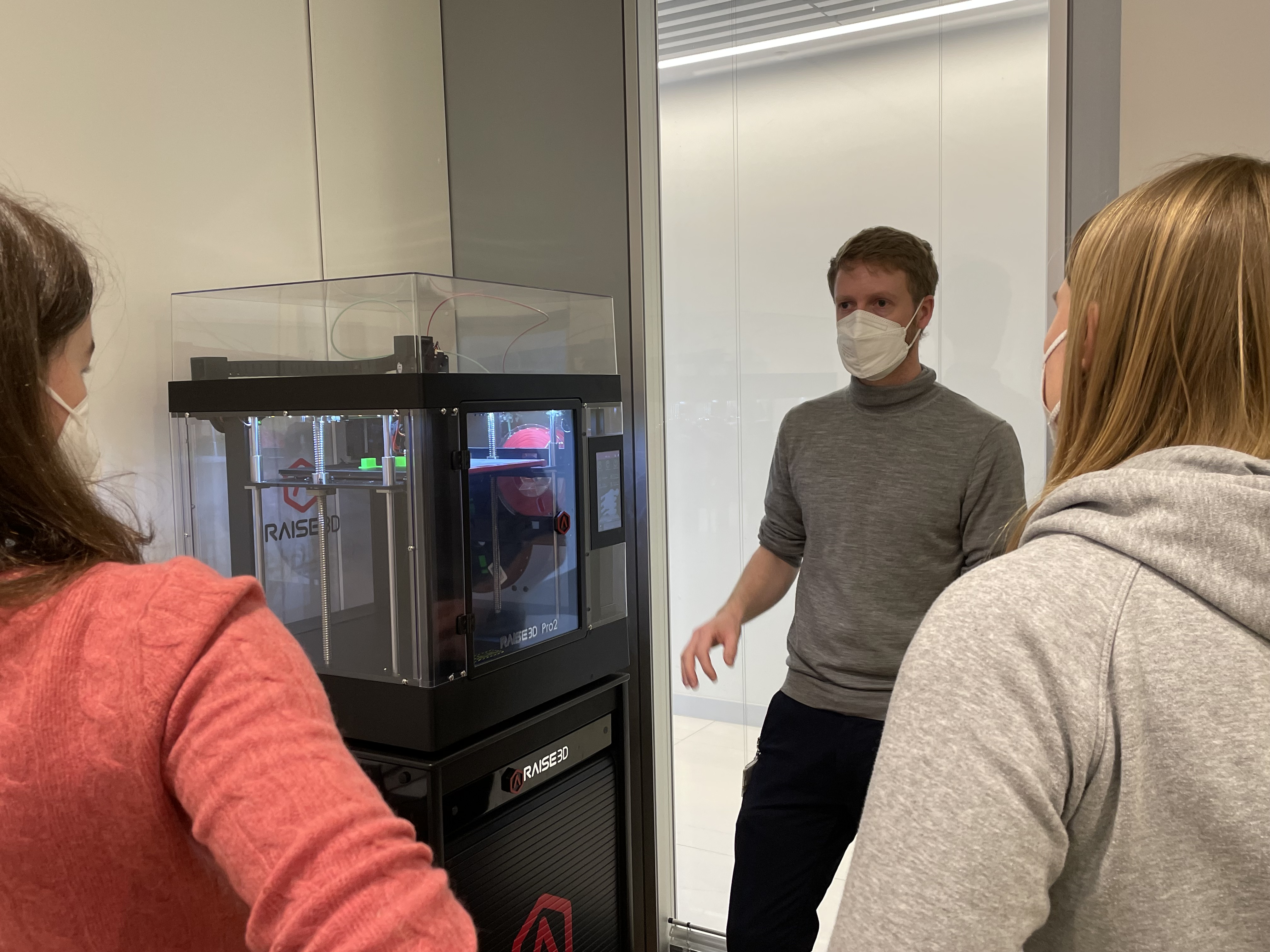

The future of 3D printing in medicine: students explore the UKM's 3D-Lab

Last Friday, we welcomed a group of students from the Biomedical Engineering course at Münster University of Applied Sciences to the 3D-Lab. As part of the pilot lecture “Fundamentals of Additive Manufacturing”, they were given exciting insights into the role of 3D printing in clinical research and medical applications. From patient-specific implants to innovative manufacturing technologies - the budding engineers were able to experience first-hand how 3D printing is helping to shape the future of medicine.

The exchange between research, teaching and practice is essential in order to further develop new technologies and integrate them into medical care. We look forward to accompanying the next generation of engineers and researchers on their journey and working together on the innovations of tomorrow!

Silver is worth its weight in gold for implants: Martin Schulze accepted into the Innovate! academy

Münster (mfm/jg) - Your own body already causes enough problems - but what if the knee prosthesis also becomes infected? In order to prevent such cases, Priv.-Doz. Dr. Dr. Martin Schulze from the University of Münster is leading a research team that is developing anti-infective coatings for implants. He has now been accepted into the Innovate! academy of the Joachim Herz Foundation, which is funding the project with 250,000 euros over two years.

The “race for surface” begins as soon as an implant is inserted: The body's own cells and bacteria fight to see who reaches the implant surface first. “If the bacteria win this race, an infection can develop,” explains Schulze, who not only heads the project but also the research area of experimental orthopaedics. The infection rate for tumor prostheses is up to 20 percent and rises to up to 40 percent after revision surgery; the infections are often severe. “We are therefore working on new materials that will both prevent implants from becoming infected and offer better treatment options in the event of infections,” says Schulze.

Click here for the article (German)

Day of the open OR

On November 29, 2024, the first Day of the open OR Day took place at the UKM. From 10 a.m. to 6 p.m., visitors were able to explore our outpatient surgery center. A varied program was on offer, ranging from guided tours of the operating theatre to exciting presentations on surgical techniques and insights into modern medical technology. Our 3D-printed models also attracted the attention of visitors and contributed significantly to the success of the event. We are proud that we were able to contribute to the success of the first event with our innovative contributions. Many thanks to all participants and of course a big thank you to our great UKM colleagues who made this day possible. We are delighted with the great interest and positive feedback!

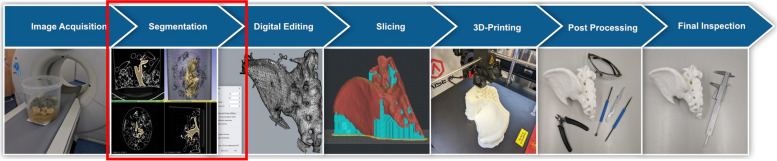

Insights into geometric deviations of medical 3d‑printing: a phantom study utilizing error propagation analysis

Background The use of 3D-printing in medicine requires a context-specific quality assurance program to ensure patient safety. The process of medical 3D-printing involves several steps, each of which might be prone to its own set of errors. The segmentation error (SegE), the digital editing error (DEE) and the printing error (PrE) are the most important partial errors. Approaches to evaluate these have not yet been implemented in a joint concept. Consequently, information on the stability of the overall process is often lacking and possible process optimizations are difficult to implement. In this study, SegE, DEE, and PrE are evaluated individually, and error propagation is used to examine the cumulative effect of the partial errors.

Methods The partial errors were analyzed employing surface deviation analyses. The effects of slice thickness, kernel, threshold, software and printers were investigated. The total error was calculated as the sum of SegE, DEE and PrE.

Results The higher the threshold value was chosen, the smaller were the segmentation results. The deviation values varied more when the CT slices were thicker and when the threshold was more distant from a value of around -400 HU. Bone kernel-based segmentations were prone to artifact formation. The relative reduction in STL file size [as a proy for model complexity] was greater for higher levels of smoothing and thinner slice thickness of the DICOM datasets. The slice thickness had a minor effect on the surface deviation caused by smoothing, but it was affected by the level of smoothing. The PrE was mainly influenced by the adhesion of the printed part to the build plate. Based on the experiments, the total error was calculated for an optimal and a worst-case parameter configuration. Deviations of 0.0093 mm ± 0.2265 mm and 0.3494 mm ± 0.8001 mm were calculated for the total error.

Conclusions Various parameters affecting geometric deviations in medical 3D-printing were analyzed. Especially, soft reconstruction kernels seem to be advantageous for segmentation. The concept of error propagation can contribute to a better understanding of the process specific errors and enable future analytical approaches to calculate the total error based on process parameters.

To the paper

Visit to Formnext 2024 in Frankfurt am Main

Our visit to Formnext 2024 in Frankfurt am Main was a fascinating insight into the latest trends and technologies in additive manufacturing, particularly in the field of 3D printing. We were able to hold in-depth discussions with leading experts and gather valuable information for our medical point-of-care research.

This experience will now be channelled into our projects and help us to further exploit the possibilities of 3D printing technology in medicine. Formnext not only inspired us, but also showed us possible new avenues for future research initiatives.

Visit to the DKOU 2024 in Berlin - Wanting the future. Making the future.

Between 22 and 25 October 2024, we took part in the German Congress of Orthopaedics and Trauma Surgery (DKOU) in Berlin. Our doctoral candidates Lukas Jürgensen and Melanie Nonhoff had the opportunity to present our current research findings, which focus on additive manufacturing at the point of care and the development of anti-infective coatings.

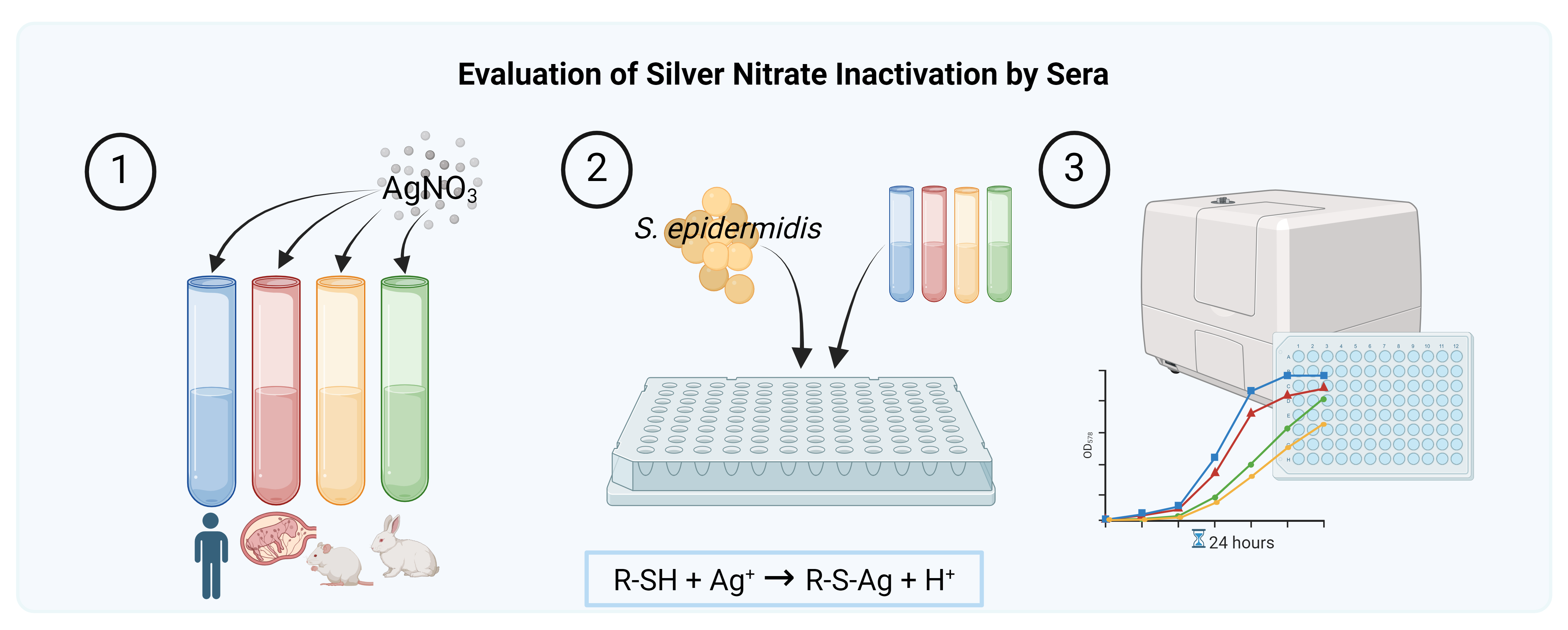

The presentations were very well received. Particularly noteworthy was the feedback on our new in vitro model, which enables the validation of bony structures in CT. This was presented during the session ‘Technologies in teaching, 3D and patient education’. The interaction of sera with silver ions, which was presented in the poster session ‘Basic Research Poster: Inflammation and Infection’, was also extensively discussed.

The DKOU Congress is a central event for experts in the field of orthopaedics and trauma surgery and facilitates a fruitful exchange on the latest scientific and technical advances. We are proud to be able to contribute to this dialogue and are already looking forward to participating next year.

Accuracy of pelvic bone segmentation for 3d printing: a study of segmentation accuracy based on anatomic landmarks to evaluate the influence of the observer

Background

3D printing has a wide range of applications and has brought significant change to many medical fields. However, ensuring quality assurance (QA) is essential for patient safety and requires a QA program that encompasses the entire production process. This process begins with imaging and continues on with segmentation, which is the conversion of Digital Imaging and Communications in Medicine (DICOM) data into virtual 3D-models. Since segmentation is highly influenced by manual intervention the influence of the users background on segmentation accuracy should be thoroughly investigated.

Methods

Seventeen computed tomography (CT) scans of the pelvis with physiological bony structures were identified, anonymized, exported as DICOM data sets, and pelvic bones were segmented by four observers with different backgrounds. Landmarks were measured on DICOM images and in the segmentations. Intraclass correlation coefficients (ICCs) were calculated to assess inter-observer agreement, and the trueness of the segmentation results was analyzed by comparing the DICOM landmark measurements with the measurements of the segmentation results. The correlation between segmentation trueness and segmentation time was analyzed.

Results

The lower limits of the 95% confidence intervals of the ICCs for the seven landmarks analyzed ranged from 0.511 to 0.986. The distance between the iliac crests showed the highest agreement between observers, while the distance between the ischial tuberosities showed the lowest. The distance between the upper edge of the symphysis and the promontory showed the lowest deviation between DICOM measurements and segmentation measurements (mean deviations < 1 mm), while the intertuberous distance showed the highest deviation (mean deviations 14.5—18.2 mm).

Conclusions

Investigators with diverse backgrounds in segmentation and varying experience with slice images achieved pelvic bone segmentations with landmark measurements of mostly high agreement in a setup with high realism. In contrast, high variability was observed in the segmentation of the coccyx. In general, interobserver agreement was high, but due to measurement inaccuracies, landmark-based approaches cannot conclusively show that segmentation accuracy is within a clinically tolerable range of 2 mm for the pelvis. If the segmentation is performed by a very inexperienced user, the result should be reviewed critically by the clinician in charge.

Click here for the paper!

Admission to the Innovate! Academy for New Materials in Medical Technology of the Joachim Herz Foundation

As of 1st October, PD Dr Dr Schulze is a member of the Innovate! Academy of the Joachim Herz Foundation. This renowned funding initiative offers him targeted support for his research project on the development of anti-infective coatings over a period of two years. The aim of the funding is to gradually transfer the research results into clinical application and thus enable access for patients.

The funding from the Innovate! Academy includes both financial resources and advisory support specifically designed to facilitate the translation of innovative ideas into clinical applications. The Academy relies on a network of interdisciplinary researchers who are advancing their projects at similar stages of development and can thus learn and benefit from each other.

Participation in the Annual Meeting of the European Bone and Joint Infection Society (EBJIS) 2024 from 25 to 28 September in Barcelona

Melanie Nonhoff and PD Dr Jan Pützler attended this year's Annual Meeting of the European Bone and Joint Infection Society (EBJIS) in sunny Barcelona as representatives of Experimental Orthopaedics. The four-day event provided an ideal platform for exchanging the latest findings and innovations in the field of bone and joint infections with colleagues from all over Europe. Melanie Nonhoff was able to present the results of an in vivo biocompatibility study on anti-infective silver coating in the auditorium and provide valuable impulses for future research approaches.

Following the meeting, Dr Pützler began his journey as part of the EBJIS Travelling Fellowship, which took him to leading clinics and research institutions in Europe. With stops at the Hospital Clinic of Barcelona, the University Hospital Leuven and the Medical University of Vienna, he had the opportunity to gain valuable insights into practice and exchange ideas with international experts.

AM in medical technology - Between certification and the operating table

At University Hospital Münster, 3D printing is supporting both patient care and research.

Before you start applying 3D printing to the field of medicine, you should definitely know the rules inside and out – which is something Dr. Martin Schulze has been spending a lot of time on in recent years. The engineer and orthopedist heads the 3D-Lab at University Hospital Münster (UKM). With the help of a team that includes printing experts, radiologists, microbiologists, and other engineers, Dr. Schulze not only oversees the 3D printing of incision templates and models for preoperative planning; he also deals with the frameworks that are meant to ensure UKM’s compliance with the relevant regulations.

For an example of how complicated that can be in a sector as highly regulated as medicine, look no further than the relatively simple process of 3D-printing an anatomical model. Here, it makes a big difference whether the model will “only” be used for demonstration or to explain a procedure to a patient, or for planning an upcoming operation. It might even need to be a sterile object that will be used for tactile navigation purposes in the operating theater.

More here!

The 3D-Lab of Orthopaedics (Clinic for General Orthopaedics and Tumor Orthopaedics, Director: Prof. Georg Gosheger) provides support in the treatment of complex injuries to war victims

As part of the solidarity agreement with Ukraine, Ukrainian patients who cannot be adequately treated there due to the war are repeatedly treated at the UKM. A 26-year-old soldier whose thigh had been shattered by a shell fragment just below the hip could be saved in his home country - but the complex operation required to save his right leg from complete amputation could not be performed there. At the UKM, numerous disciplines are treating the young man in close cooperation. In order to be perfectly prepared, the surgeons planned the operation using a 3D model. | aw

Zum Abspielen des Videos wird dieses von einem Webserver der Firma Google™ LLC geladen. Dabei werden Daten an Google™ LLC übertragen.

The Influence of Different Sera on the Anti-Infective Properties of Silver Nitrate in Biopolymer Coatings

The widespread prevalence of periprosthetic joint infections (PJIs) poses significant challenges in orthopedic surgeries, with pathogens such as Staphylococcus epidermidis being particularly problematic due to their capability to form biofilms on implants. This study investigates the efficacy of an innovative silver nitrate-embedded poly-L-lactide biopolymer coating designed to prevent such infections. The methods involved applying varying concentrations of silver nitrate to in vitro setups and recording the resultant bacterial growth inhibition across different serum environments, including human serum and various animal sera. Results highlighted a consistent and significant inhibition of S. epidermidis growth at all tested concentrations in each type of serum without adverse interactions with serum proteins, which commonly compromise antimicrobial efficacy. This study concludes that the silver nitrate-embedded biopolymer coating exhibits potent antibacterial properties and has potential for use in clinical settings to reduce the incidence of PJIs. Furthermore, the findings underscore the importance of considering serum interactions in the design and testing of antimicrobial implants to ensure their effectiveness in actual use scenarios. These promising results pave the way for further research to validate and refine this technology for clinical application, focusing on optimizing silver ion release and assessing biocompatibility in vivo.

Click here for the paper!

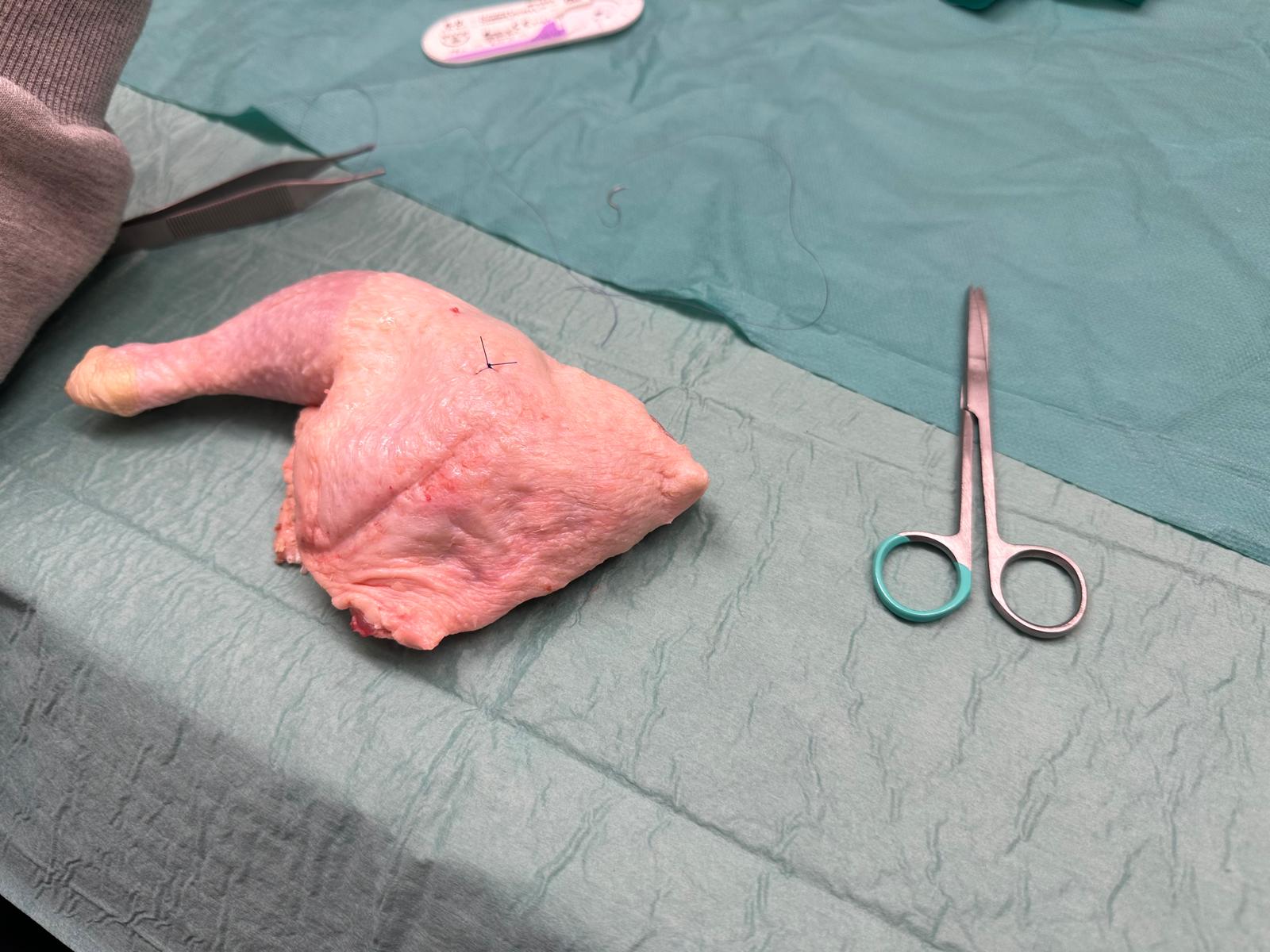

Suturing Course for Our New Generation

Our students gain practical experience right from the start of their studies. Our suturing course offers the ideal opportunity to learn how to use typical instruments, especially for surgical disciplines. Before working on real wounds, the participants first practise on oranges, bananas and chicken thighs in the course.

We had a lot of fun and look forward to seeing you in the OR again soon!

Lukas Jürgensen receives doctoral scholarship from the DGOOC

We congratulate our medical doctoral student and resident physician at the Clinic for General Orthopedics and Tumor Orthopedics Lukas Jürgensen on receiving the doctoral scholarship from the German Society for Orthopedics and Orthopedic Surgery (DGOOC). Mr. Jürgensen is awarded for his achievements and commitment in research on additive manufacturing at the point-of-care and individualized care of orthopedic patients. As part of our team, he has made a significant contribution to establishing the technology at the site and making it usable for patient care.

We look forward to continuing our collaboration!

Joint Meeting of the Co-Operations from Münster and Enschede

A delegation of medical staff from various specialist departments at the UKM visited the cooperation partner in Enschede - including PD Dr Dr Schulze for an exchange of experiences on the topic of 3D printing at the point of care, which we would like to work on more closely in the future.

Click here for the article

PD Dr Dr Martin Schulze as a guest appearance on Druckwelle

Druckwelle is a podcast from ingenieur.de on the topic of additive manufacturing. In the last episode (No. 81 from 04 April 2024), PD Dr Dr Martin Schulze was a guest to talk about patient care at Münster University Hospital with the help of the new 3D-Lab. Listen in at the following links! (German)

About the Podcast

Without the third dimension, everything is flat. Additive manufacturing is the trend in production and industry. At Druckwelle, we bring leading minds in additive manufacturing to the microphone to explain 3D printing to you in vivid detail. The experts explain new printing technologies and materials. They evaluate developments and give practical tips.

VDI news editor Stefan Asche has been familiarising himself with the trend technology for years. As your host, he presents a new episode of Druckwelle every fortnight on Thursdays.

About the Episode

Münster University Hospital is the first hospital in the world to be authorised to additively manufacture and use medical products in close proximity to patient care.

So far, the experts have printed personalised templates for cutting and drilling, among other things. They enable high-precision work, for example in the border area between carcinoma and healthy tissue.

The doctors also produce bone models to which implants are adapted. A third area of application is models that are used to explain to patients what treatment is planned.

The Münster-based company still only uses plastic printers, including a large-volume SLS printer weighing 1.4 tonnes and a DLP printer.

In this episode, Martin Schulze, a doctor of engineering and senior physician, explains the details of applications. He also ventures a prediction of what the intersection of engineering and high-tech medicine could produce in the future.

Customised implants, models and instruments at the point of care

Münster (mfm/sw) - 3D printing has almost become part of everyday life - and yet it can do so much more: for example, produce patient-specific implants, reproduce entire organ systems, such as the heart and parts of the aorta, or print individualised drilling and sawing templates for bones for use in the operating theatre. The opening of a unique facility in Germany shows how the University Medical Center in Münster will use this future technology in the future: on Monday [19 February], the "3D Lab" integrated into the Experimental Orthopedics Department at the Faculty of Medicine was officially put into operation. The lab, which has received around one million euros in funding to date, is intended to pool expertise and knowledge relating to 3D printing and make it available for medical research - and subsequently for regular patient care.

Click here for the Article (German)

Click here for the WDR Report (German)

Click here for the Westfälische Nachrichten Report (German)

Visit to the AM Medical Days in Berlin

We attended the AM medical Days again this year and were looking forward to the exciting exchange with experts from the field of additive manufacturing in medicine.

This year, we reported in a keynote lecture on how 3D printing is safely designed for patient care at the point of care. At the UKM, we support our doctors by providing sterile patient-specific anatomical models for surgery through a certified process, thereby contributing to the improvement of therapy.

Pre-Audit for MDR Certification at the Point of Care

On 20 and 21 November 2023, our team received another visit from Gregor Reischle (AM Entrepreneur). He conducted a pre-audit in accordance with ISO/ASTM52920 of our additive manufacturing process using DLP technology and prepared us for the upcoming audit by a notified body. The 3D printing process is now MDR-compliant.

To ensure patient safety, the entire process in which additive manufacturing is used will be set up and certified in accordance with the requirements of the Medical Device Regulation (MDR) in the long term.

We look forward to quality-assured clinical applications!

Shock Wave-Activated Silver-Loaded Biopolymer Implant Coating Eliminates Staphylococcus epidermidis on the Surface and in the Surrounding of Implants

Bacterial biofilms on foreign surfaces are considered a primary cause of implant-related infections, which are challenging to treat. A new implant coating was developed, containing anti-infective silver within a biocompatible polymer carrier substance. In addition to its passive effect on the implant surface, highly concentrated anti-infective silver can be released as needed via the application of high-energy shock waves. This intervention could be applied transcutaneously in a clinical setting without the need for additional surgery. We investigated the inhibition of biofilm formation and the effectiveness of eradication after activation of the coating via shock waves in an in vitro biofilm model using Staphylococcus epidermidis RP62A. This was performed via scanning electron microscopy and quantitative microbiology. Additionally, we examined the cytotoxicity of the new coating on normal human fibroblasts and Saos-2 osteoblast-like cells, depending on the silver concentration. All studies were compared to uncoated titanium surfaces Ti6Al4V and a conventional electroplated silver coating. Cytotoxicity toward normal human fibroblasts and Saos-2 osteoblast-like cells increased with higher silver content but remained tolerable at 6%. Compared to uncoated Ti6Al4V and the electroplated silver coating, the new coating with a silver content of 4% and 6% exhibited a significant reduction in adherent bacteria by a factor of approximately 1000. This was also evident via microscopic examination of the surface morphology of the biofilms. Furthermore, following shock wave activation, no bacteria were detectable on either the implant or in the surrounding fluid after a 24 h period.

Click here for the Paper

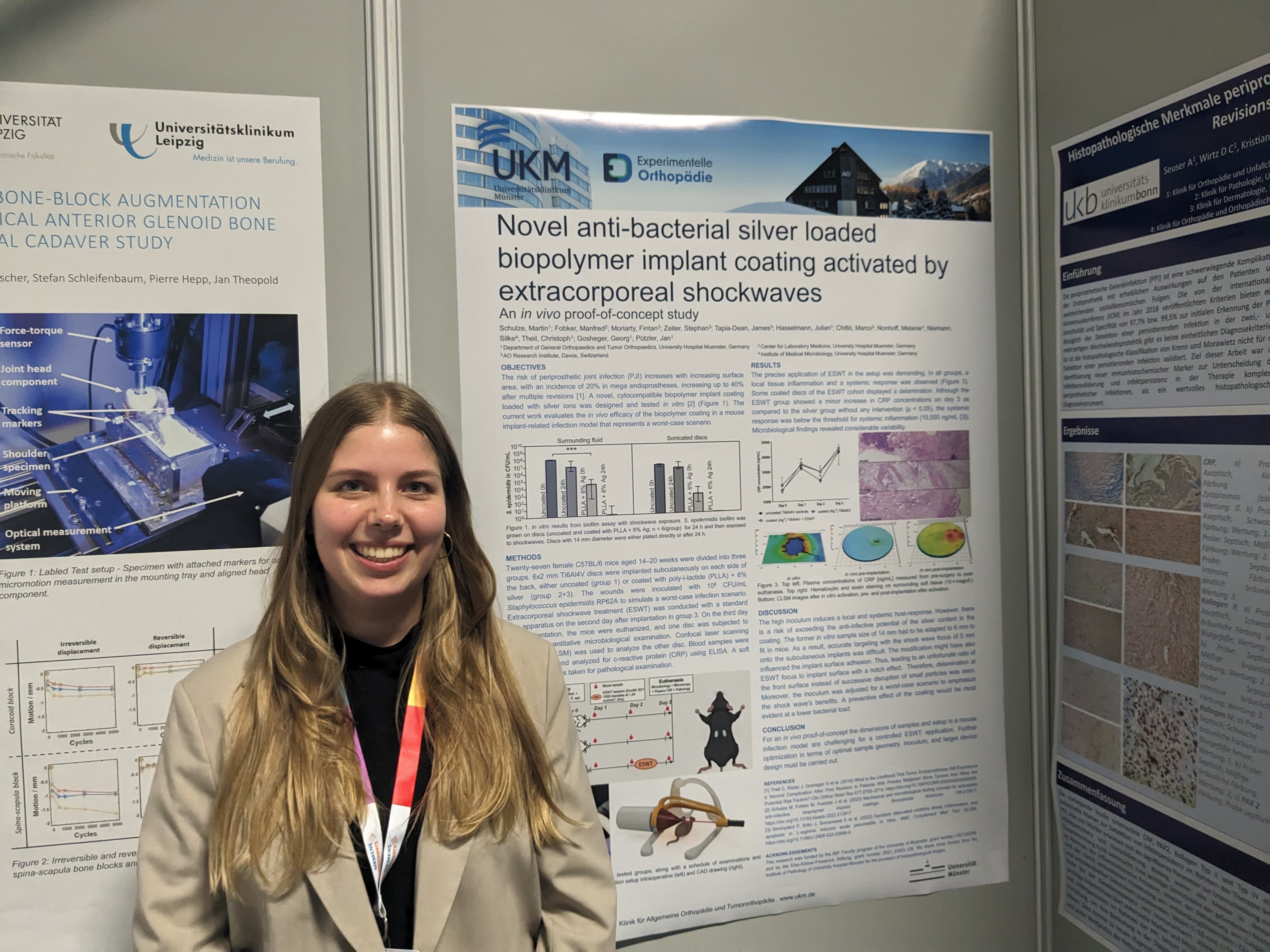

Visit to the DKOU 2023 in Berlin - Expertise in Quality and Progress

On 26 October 2023, our team took part in the German Congress for Orthopedics and Trauma Surgery (DKOU) in Berlin. There we presented exciting research results in the fields of anti-infective coatings and additive manufacturing at the point of care.

Our latest results were successfully presented by our PhD students Lukas Jürgensen and Melanie Nonhoff in the poster sessions "Tumour Surgery and Upper Extremity" and "Experimental III".

The DKOU congress is an important platform for professionals in orthopedics and trauma surgery to share the latest advances. We are proud to contribute to this exchange of knowledge and look forward to participating again next year.

MDR-Compliant Certification at the Point of Care

The kick-off meeting for the certification of 3D-printed anatomical models took place recently. The aim is to provide sterile patient-specific models for operations. This means that models can not only be used for surgical preparation and planning, but can also be repeatedly used by the surgical team during complex procedures. This makes complex operations easier and increases patient safety.

The Experimental Orthopedics team has enlisted the active support of an expert in the form of Gregor Reischle (AM Entrepreneur). Certification in accordance with the Medical Device Regulation (MDR) is our declared goal for the near future.

We look forward to the next steps!

New High-End Acquisition: 1.4 t Printer Becomes the Heart of the 3D Laboratory at Münster University Medical Center

Report from 17.07.2023

Münster (mfm/sw) - What weighs almost one and a half tonnes, cost several hundred thousand euros and had to be delivered by crane? Exactly: the new 3D printer at Münster University Medical Center. After the complex large-scale device was initially delayed due to extensive remodelling work, it has now been hoisted by crane into its destination building - the 3D laboratory in the Orthopedics Clinic - and is almost ready for use. From now on, the new acquisition will help with research into new technologies in orthopedics and thus contribute to individualised patient care. The head of the 3D laboratory, physician and engineer Dr Martin Schulze, speaks of a "step into a new future of medicine at the Münster site". The investment of around 530,000 euros in the device was financed primarily with EU funds from the REACT programme, which the Faculty of Medicine at the University of Münster and the University Hospital for Orthopedics topped up from their own funds.

Click here for the Article (German)

Investigations Accurate to the Nanometre: Department of Mechanical Engineering Acquires Confocal Microscope

Report from 03.07.2023

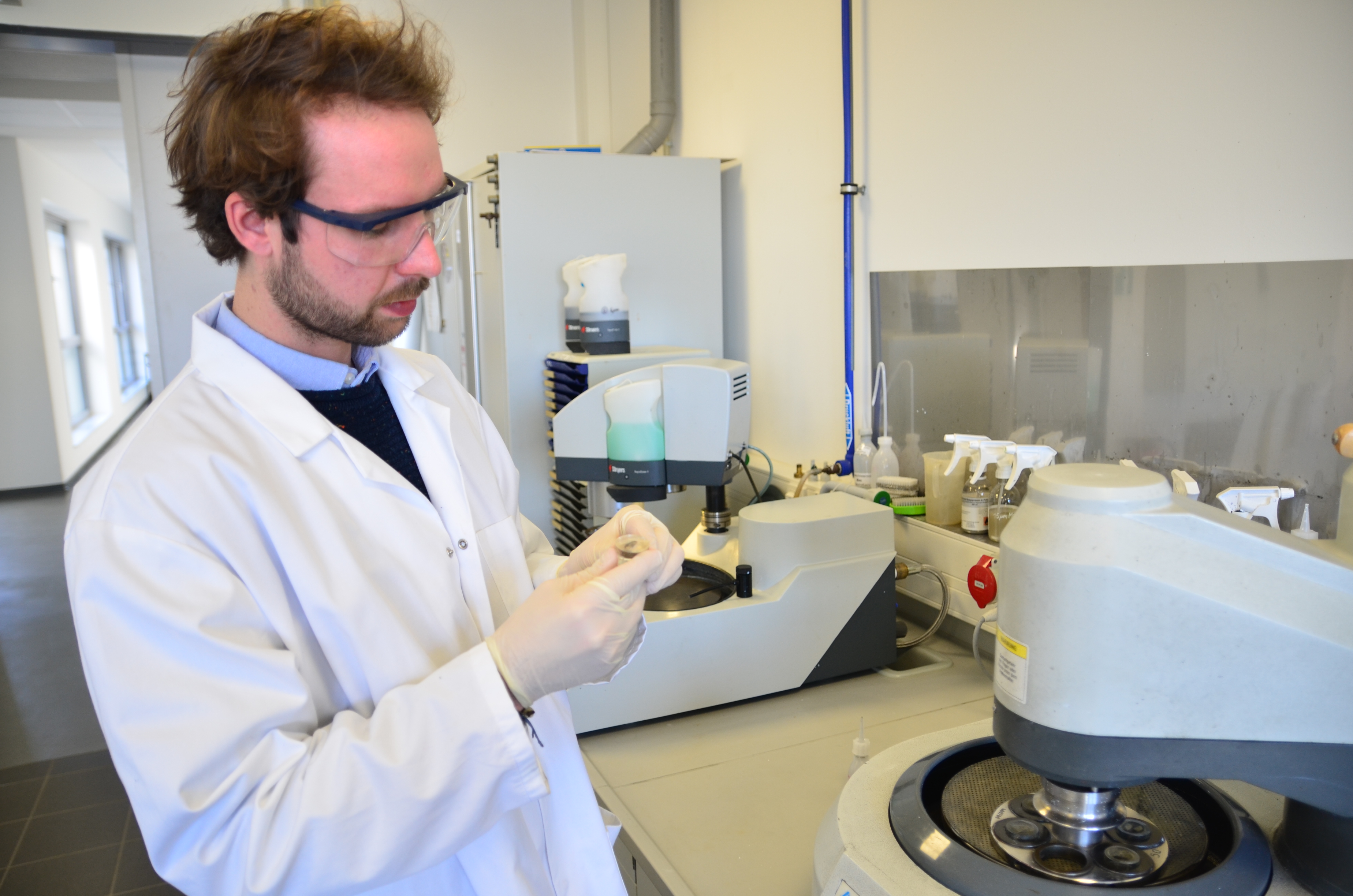

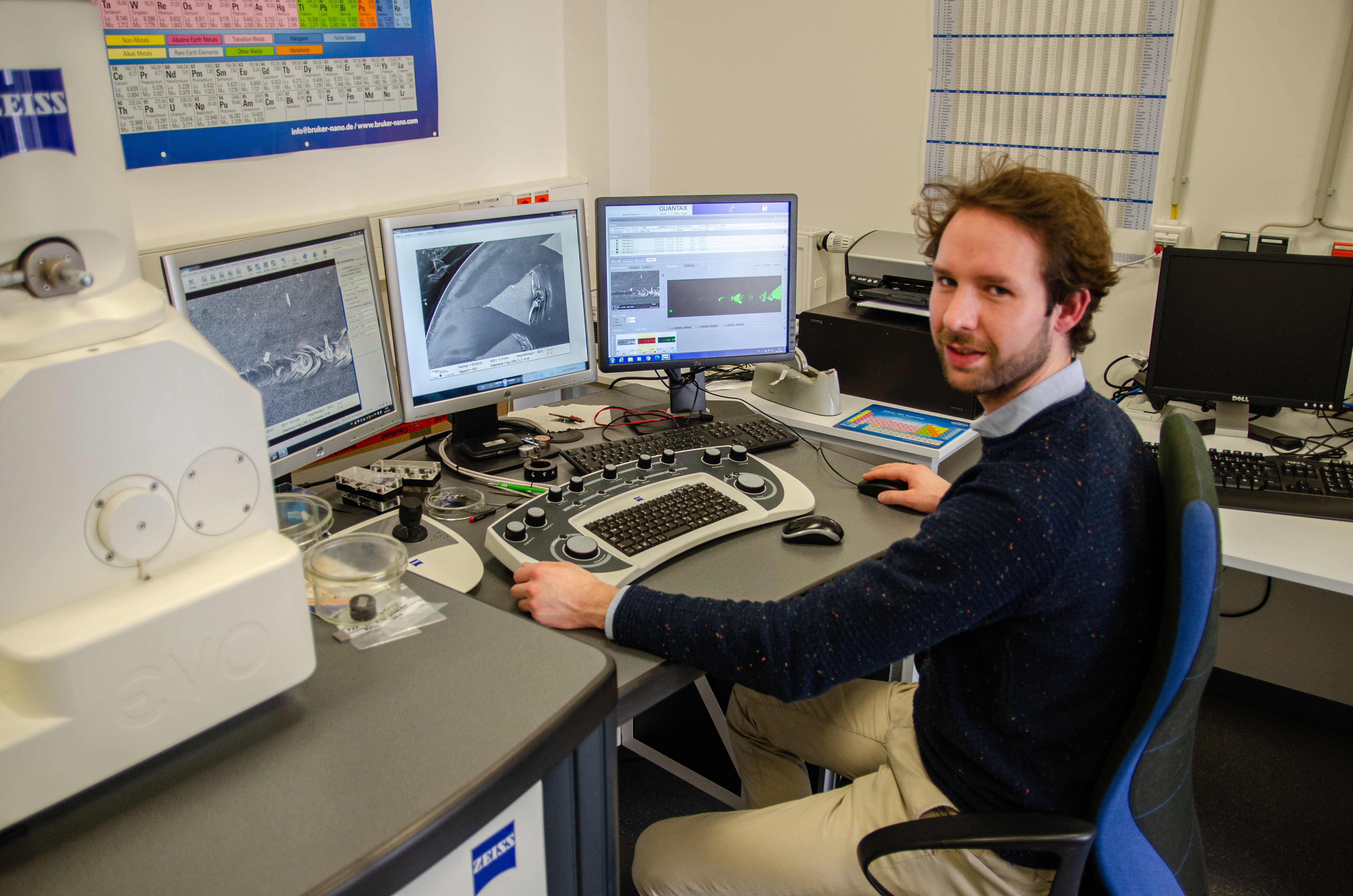

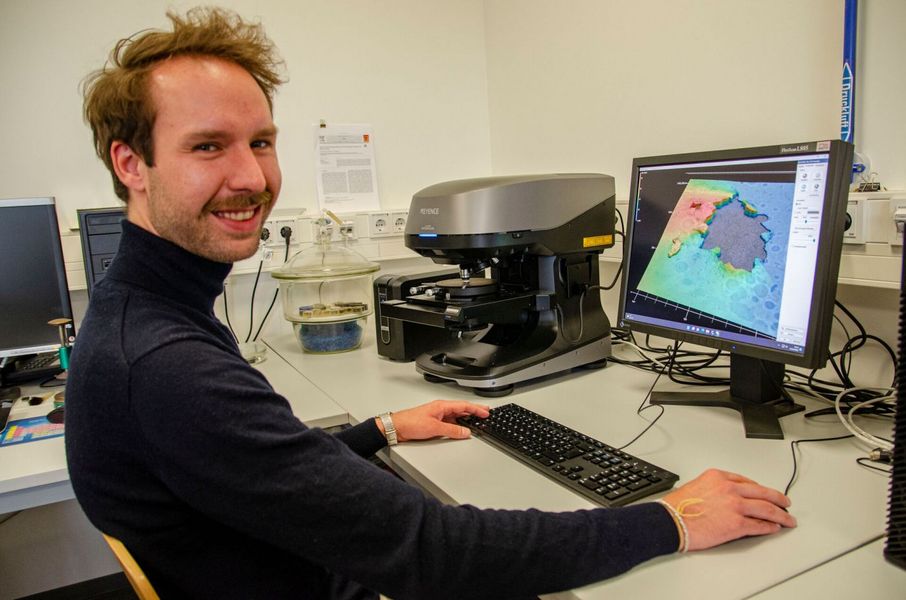

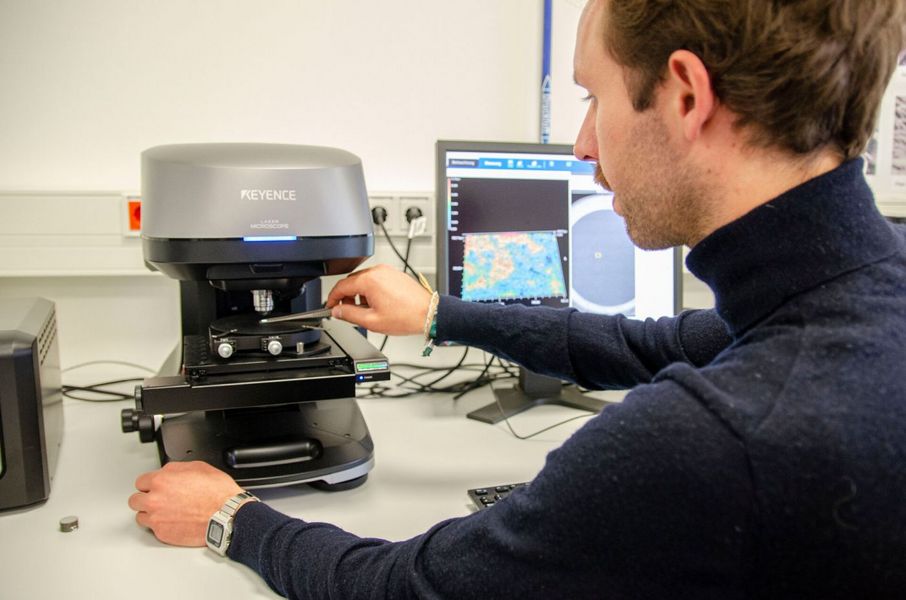

The laser beam scans the sample piece by piece. Only a fraction of the silver ion coating to be analysed is examined using a pinhole - and little by little, the confocal microscope is able to create a 3D model that takes Julian Hasselmann's research a decisive step forward. The acquisition is new to the Materials Technology Laboratory at the Department of Mechanical Engineering, which is headed by Prof Dr Gerhard Gevelmann and Dr Miriam Laubrock. The confocal microscope not only helps doctoral students like Hasselmann, but also prepares students even better for their future engineering careers.

Click here for the Article (German)

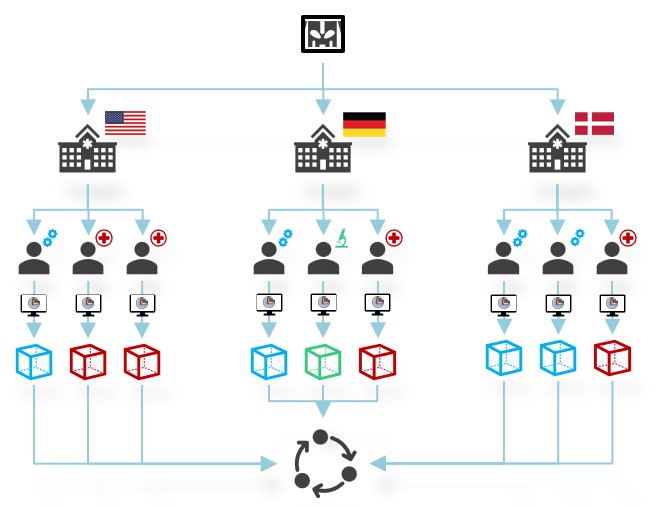

MGA Medical Hospitals AM Multicenter Study

Together with our MGA working group hospitals we invite you to a multi-center study. Using DICOM datasets of pelvic CTs, an inter/intra-observer study will be performed and quality assessments of pressure parameters for anatomical models will be performed.

In our project we want to compare

Segmenters with different levels of experience

Segmentation software: free (freeware) vs. certified

MEX printers/printer/AM technologies

and others...

Who should participate:

Medical professionals (surgeons, radiologists)

Clinical designers/engineers

and others...

Further information can be found under the following links:

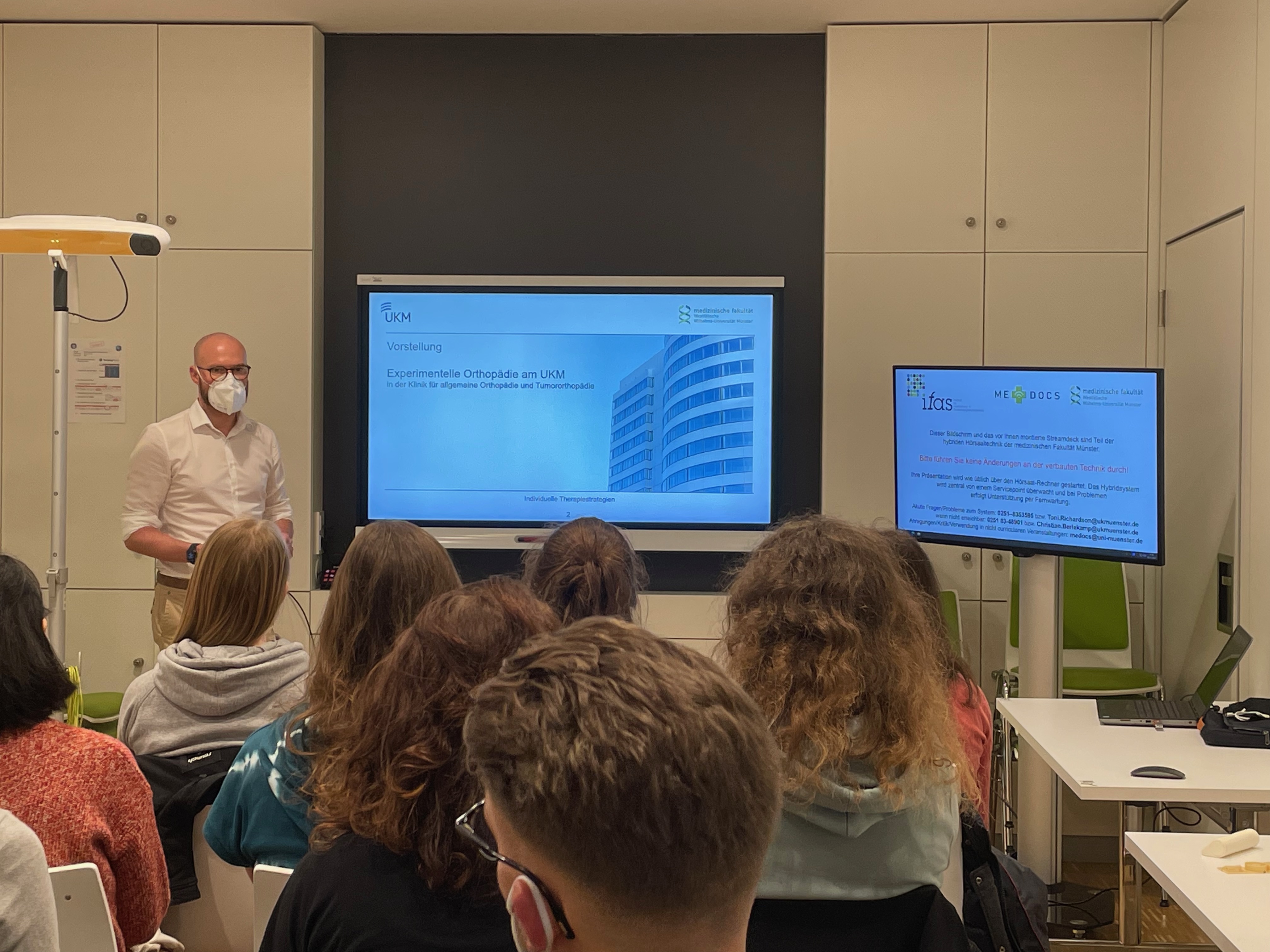

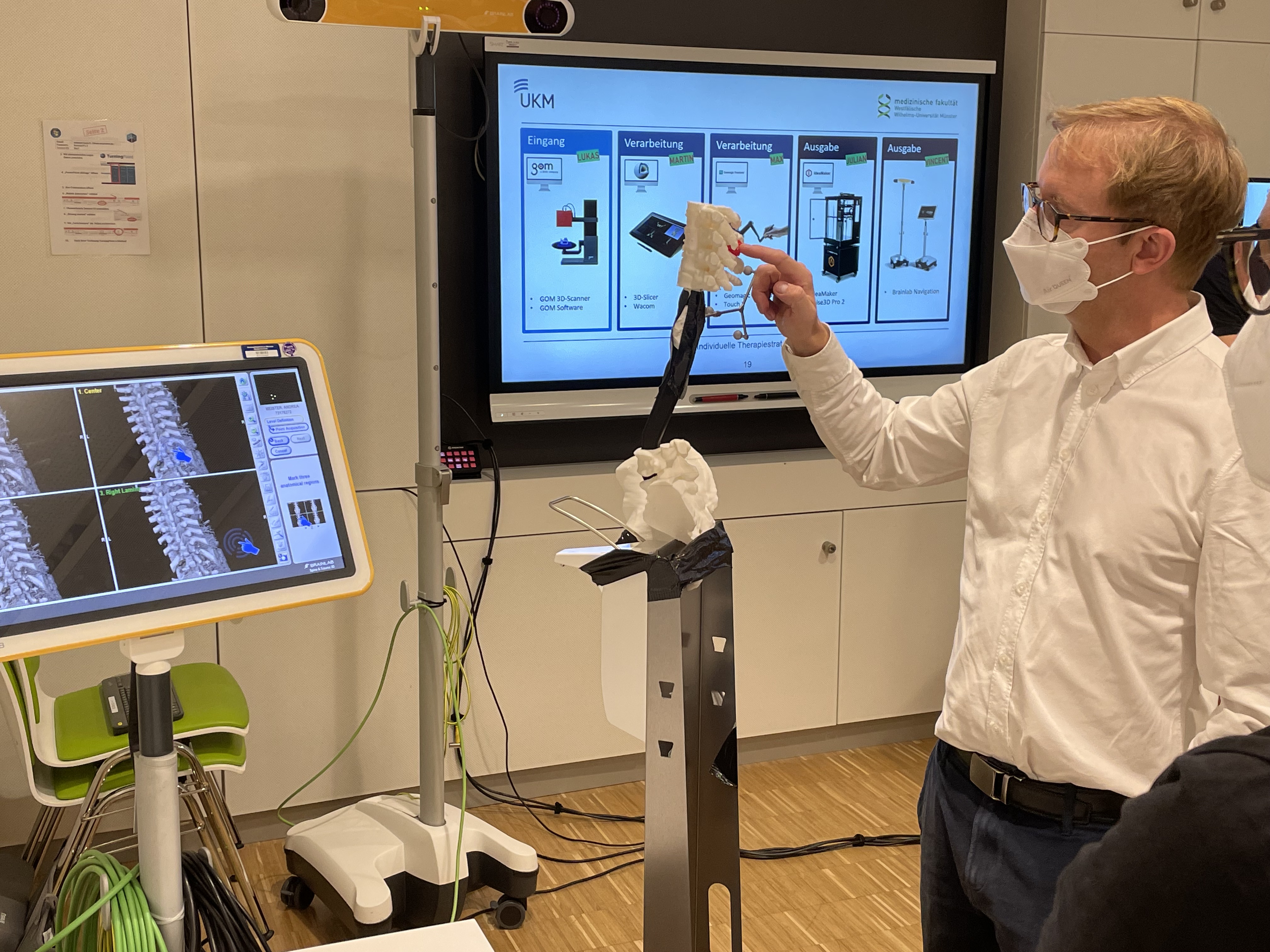

Teaching Day 2022 - Workshop of Experimental Orthopedics

This year's Teaching Day took place again on 9 November and Experimental Orthopedics was there with two workshops!

Medical students from all semesters had the opportunity to take a look at research and development for our patient-centered treatment. At four stations, they were able to get hands-on and experience point-of-care solutions through to navigated surgery on a 3D printed model.

A really great event with enthusiastic students - thank you!

Visit to the DKOU 2022 in Berlin - #PassionForThePatient

The German Congress of Orthopedics and Trauma Surgery (DKOU) took place in Berlin from 25 to 28 October 2022 - a complete success for our Experimental Orthopedics team!

With over 10,000 participants, the DKOU is the largest specialist congress for O and U in Europe. In addition to networking and partnerships, it was an ideal platform to present our current clinical and experimental research results in three lectures. In the basic research session, we had the opportunity to present our activatable anti-infective implant coating to a broad audience of medical and medical technology specialists.

We take home great impressions, a positive response and the desire to move into clinical application and look forward to seeing you again at future congresses.

New Implant Coatings Help in the Fight against Bacteria

Münster/Steinfurt (16 April 2021). When a person is fitted with a prosthesis, a race begins in the body: The body's own cells ensure that the implant is accepted - but if bacteria get onto the surface of the prosthesis first, this leads to an infection and, as a result, often to another operation. In order to decide this so-called "race for surface" in favour of the patient, medical technicians are working on preventing infections with special coatings. Dr Martin Schulze at Münster University Hospital (UKM) is one of them. He and his team want to improve the quality of prostheses with a new coating system. They are receiving support from the Department of Mechanical Engineering at Münster University of Applied Sciences: in his master's thesis, student Julian Hasselmann has developed a test concept for the mechanical characterisation of this new coating system.

Click here for the Article (German)